Have you ever heard about engine injection? Simply put, it is the system that delivers fuel to the combustion chamber. So, how does this mechanism work? What are the common injection failures? We explain everything about this distribution component!

Are you looking for a car scanner ?

To fully understand the injection system and the potential failures, it is essential to grasp its operating principle and the components it consists of.

The components of the injection system

Here are the components of an engine injection system:

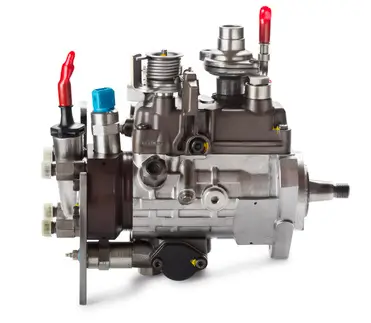

- The high-pressure fuel pump: it delivers fuel to the common rail.

- The common rail: it increases fuel pressure, which varies between petrol and diesel vehicles.

- The injector: this is a valve responsible for sending fuel into the cylinders.

- The return pipes: they allow fuel circulation.

- The engine ECU: it collects data from the engine sensors and controls the opening of the injectors.

Introduction to mechanical injection

Engine injection appeared with the disappearance of carburettor engines in the late 1960s. It operates differently depending on the type of engine, petrol or diesel. Below is how mechanical injection works for petrol engines:

- First, petrol is pressurised by an electric pump. This component is called the injection pump.

- This injection pump contains the camshaft, which distributes fuel to each cylinder installed in the car.

- Fuel needs are then managed by a regulator.

For diesel engines, the engine injection system is managed by a rotary distributor pump. This pump has three functions:

- It sends diesel under pressure to the injectors.

- A regulator is incorporated into this pump. It manages the amount injected into the engine based on parameters defined by the engine ECU.

- With the help of an auxiliary pump, the distributor pump brings diesel from the tank to the engine.

This method is now obsolete and has been replaced by electronic injection, which allows for more precise engine injection management.

Electronic engine injection

This is the most widely used method today. It is managed by the engine ECU. This injection method optimises fuel consumption and reduces pollution. For the ECU to accurately dose the fuel, it requires several pieces of information, such as:

- The engine water temperature

- The position of the pistons

- The quality of exhaust gases

- The engine speed

- The accelerator position determined by the accelerator pedal

- The quantity and temperature of the intake air

Here is the principle of electronic injection (in modern vehicles): Fuel is delivered from the tank to the injection pump. It is then sent to a common rail to reach approximately 2000 bars of pressure for diesel engines. After pressurisation, the fuel is sent to the injectors, whose valves open at the right time to inject fuel into the engine.

Difference between direct and indirect injection

Let’s start with indirect engine injection: it operates differently depending on the type of engine, petrol or diesel. For petrol engines, the injector is placed in the intake manifold, above the valve. It should also be noted that petrol enters the cylinder in a vaporised state, not as a liquid.

For diesel engines, the injection does not occur in the intake manifold but in what is called a pre-chamber located next to the exhaust manifold. Simply put, the air passing through the intake manifold is sent into this chamber to mix with the fuel vapour, which then ignites.

Now let’s discuss direct engine injection: here, the method is the same for both types of engines: the injector is placed, unlike indirect injection, directly in the combustion chamber.

Problems related to engine injection

How to diagnose them

Several signs can indicate that an injection failure is about to occur:

- You may experience a loss of engine power

- Black exhaust smoke

- The engine stalls

- Increased fuel consumption

- You hear an unusual noise in your diesel engine

Are you looking for a car scanner ?

Common failures

There may be an issue with a clogged engine injector. It will need cleaning. It will function as usual, but air and/or fuel will struggle to circulate.

You can clean a clogged injector yourself. There are several solutions to perform this task. However, as the operation can be meticulous, it might be better to replace it.

Finally, there are injector leakage problems. These can vary depending on whether it is a petrol or diesel engine: For petrol vehicles, the leakage may occur at the upper or lower part of the engine injector. For diesel cars, the leakage may occur at the inlet, the base, or the return pipe of the injector.

How to react in case of an engine injection failure?

To avoid injection problems, regular maintenance of your vehicle is necessary. Do not hesitate to visit a mechanic if you suspect any early signs. You can also detect engine injection failures with a diagnostic tool. To do so, simply connect your device to the OBD port of your vehicle, then display the fault code reports.

There is also a trick to start your vehicle despite an injection failure, which can be useful to avoid being stranded on the roadside. If this problem occurs, the engine warning light will illuminate on your dashboard. However, just after you turn on the ignition, it will turn off for a fraction of a second. It is during this fraction that you need to start the engine.