The camshaft sensor is essential for starting the vehicle and plays a direct role in the combustion cycle by providing engine position data to the ECU, along with the crankshaft position sensor.

Are you looking for a car scanner ?

What is a camshaft?

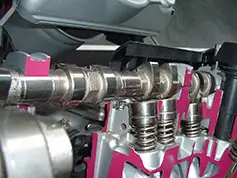

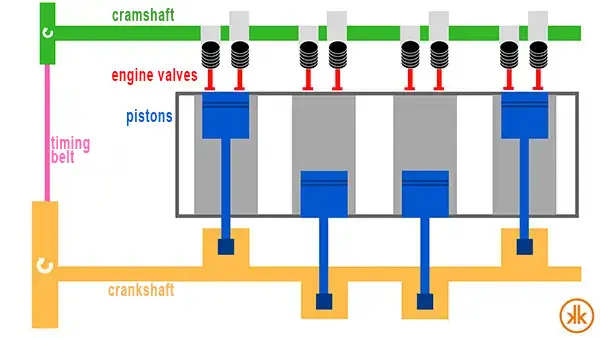

The camshaft is a key component for the proper functioning of the engine as it controls the opening and closing of the intake and exhaust valves. It is an integral part of the combustion cycle, enabling the engine to "breathe".

It is equipped with cams that press on the valves, following the engine's rhythm, thanks to a timing chain or belt that transmits the crankshaft's rotational speed.

This synchronisation is crucial for combustion and prevents the valves from colliding with the pistons, which would cause irreparable damage...

The role of the camshaft sensor

A sensor is located on the camshaft to send information about the pistons' combustion cycle to the ECU, allowing it to inject fuel at the right time and into the correct cylinder.

This also enables the engine to start, as the ECU needs to know the pistons' position at top dead centre to determine the correct ignition sequence.

Relationship with the crankshaft position sensor

However, the ECU also needs to know the pistons' position, especially at top dead centre, to complement the information received from the camshaft sensor. This is the role of the crankshaft position sensor, which measures and transmits this data based on the flywheel's rotational speed.

Simply put, both sensors are necessary for starting the vehicle: one provides the pistons' position (crankshaft sensor), and the other specifies the combustion cycle (camshaft sensor).

How the camshaft works

The camshaft's operation is relatively simple and depends on the engine speed. The timing belt or chain is connected to the crankshaft via a pulley system with a 2:1 ratio (two crankshaft rotations for one camshaft rotation).

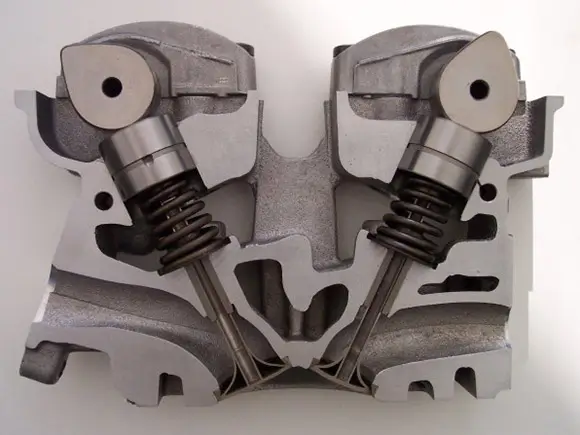

The cams then press on the valves synchronised with the engine's rhythm to create an opening in the combustion chamber (towards intake or exhaust, depending on the cycle). Springs then allow the valves to close.

The shape of the cams plays an important role in determining the degree and duration of the opening:

- The rounder they are, the longer the opening time

- The sharper and longer they are, the greater the opening degree

Are you looking for a car scanner ?

Two types of camshaft

There are two different operating modes:

- Overhead camshaft: In this configuration, a single camshaft is used to manage both intake (air and fuel) and exhaust (gas expulsion).

- Double overhead camshaft: This involves having two camshafts—one for intake and one for exhaust. This setup theoretically provides better performance, especially at high speeds. However, this is less true today as engines are more efficient than 15 years ago, and a single camshaft can now offer comparable performance.

Variable valve timing: VVT

Adjusting the shape of the cams can optimise valve openings to improve engine efficiency depending on load and speed.

Variable valve timing goes further by allowing real-time modification of the cam profiles. This is known as the VVT system (Variable Valve Timing). It enables direct control over the degree and duration of valve openings, and sometimes even the timing (earlier or later).

It generally operates using a hydraulic circuit. A solenoid controls oil pressure, allowing the ECU to position the camshaft appropriately. This position change modifies the cam opening parameters based on other data received by the ECU, particularly from the crankshaft sensor and throttle body.

The ECU also relies on data from the mass airflow sensor, throttle body, temperature sensor, and speed sensor.

How the position sensor works

The camshaft position sensor works similarly to the crankshaft sensor, using a Hall effect to generate an electrical signal, which is then transmitted to the ECU. For more details on how it works, refer to the article on the crankshaft position sensor.

Faulty sensors: symptoms

The camshaft is a component that typically lasts the vehicle's lifetime, barring accidents. However, the VVT system and camshaft sensor can fail, leading to the engine warning light turning on and the activation of limp mode.

The resulting symptoms are often the same, including:

- Difficult or impossible engine start if the sensor is faulty

- Lack of power

- Engine stalling easily at idle

- A noisy engine

Given the relationship between the crankshaft sensor, camshaft sensor, and VVT system, the above symptoms do not precisely indicate the fault, especially since limp mode can also be triggered by other faulty mechanical components.

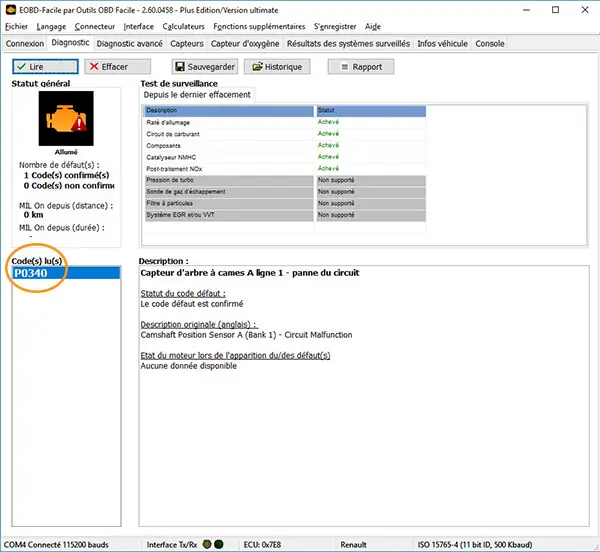

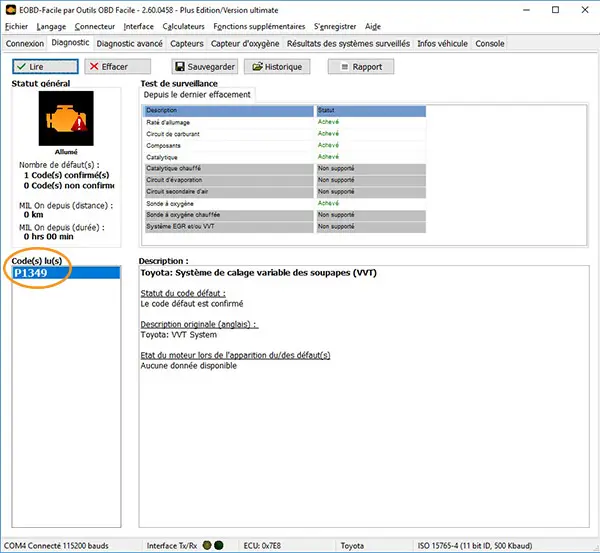

Testing and automotive diagnostics are necessary to identify the source of the fault, significantly narrowing down the search area.

Here, the fault code indicates a circuit failure in the camshaft sensor on line 1. Generally, line 1 corresponds to intake, and line 2 to exhaust, so this distinction is important. Refer to your vehicle's documentation for confirmation.

In this case, you can first check the connector, which may be poorly connected or faulty, and then test the electrical signal using a multimeter or oscilloscope.

The vehicle's VVT system may also be faulty, returning a specific manufacturer fault code (e.g., P1). In this case, we recommend consulting your vehicle's technical documentation, as VVT systems vary between manufacturers.

Are you looking for a car scanner ?