The flywheel, along with other components like the crankshaft position sensor or the camshaft, helps define the engine position, facilitates transmission and clutch operation, but it can become faulty, making symptoms hard to detect.

Are you looking for a car scanner ?

Role of the flywheel

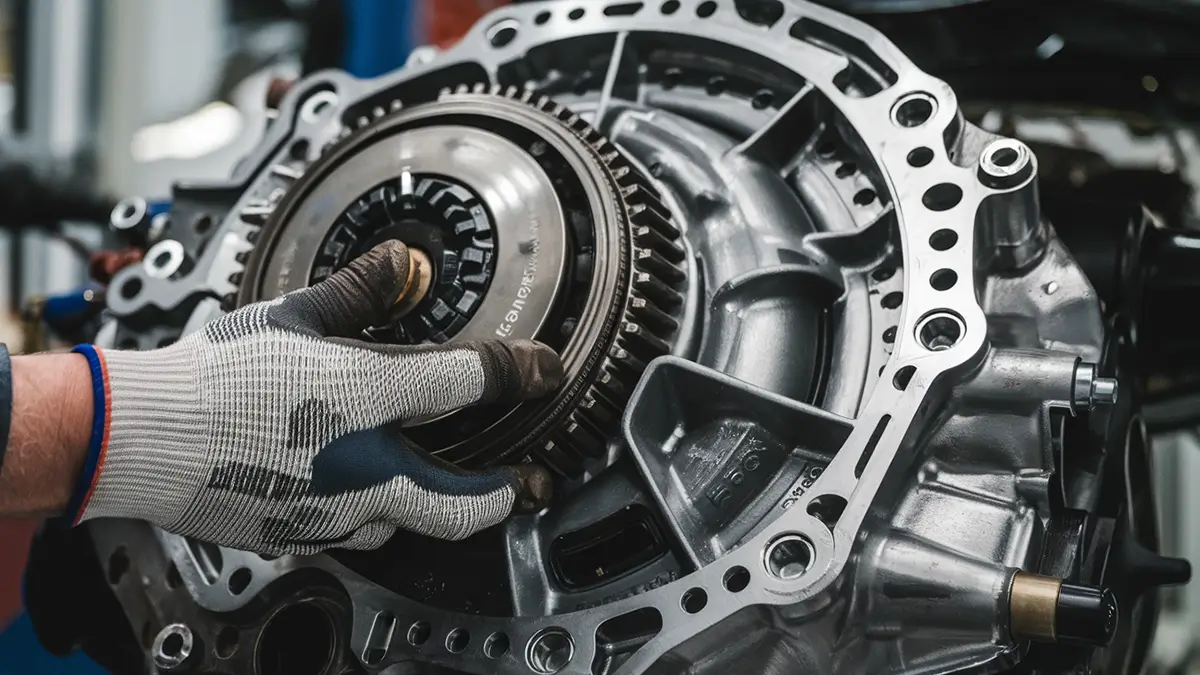

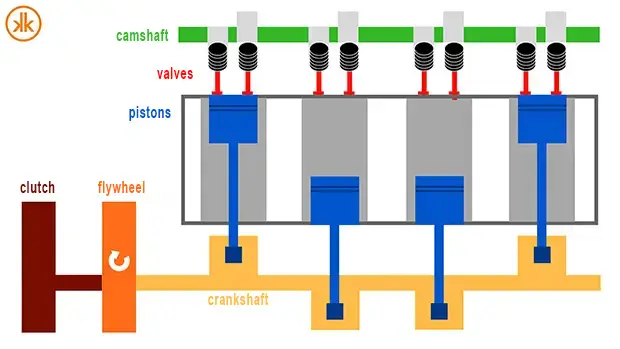

The flywheel is a mechanical disc-shaped component located between the engine and the clutch, ensuring transmission between the two. Additionally, it regulates and stabilises engine rotation to reduce jerks caused by the cylinders. This is why the flywheel is relatively heavy (between 5 and 10kg) and features springs on dual-mass models. The presence of teeth around the disc also allows the starter to engage, enabling the engine to start.

The importance of the crankshaft position sensor

The flywheel cannot do everything on its own. Its toothed edge also serves as a reference point for the crankshaft position sensor, also called the crankshaft sensor.

Simply put, this sensor sends the data it measures to the engine control unit so it can determine engine speed and fuel injection.

Are you looking for a car scanner ?

The camshaft

The crankshaft position sensor allows the control unit to know the position of the pistons, while the camshaft sensor complements this information by specifying the combustion cycle (four-stroke system).

This data is crucial since a piston positioned at the top could either be in the compression phase or the exhaust phase.

The dual-mass flywheel

Most modern Diesel engines are equipped with a dual-mass flywheel. This system uses two discs instead of one to better absorb the shocks caused by transmission.

These discs are connected by springs to dampen jerks. This solution also eliminates the need for a single flywheel, which would have been much heavier to handle the power and performance of new Diesel engines.

However, this system had long-standing reliability issues (vehicles from the 2000s), with many failing after just 80,000km. Normally, a dual-mass flywheel should last around 200,000 km, so you can understand the frustration...

The main issue stemmed from the damping springs, which wore out very quickly on early models.

Today, they are of much better quality but remain less durable over time than a traditional flywheel, which typically lasts as long as the vehicle.

It is important to note that a faulty clutch will cause premature wear of the flywheel and vice versa. The starter can also damage the flywheel at the level of its toothed wheel, but this part can be replaced directly, and such cases are rare.

Symptoms of a faulty flywheel

What are the symptoms?

In general, identifying a faulty flywheel is not always straightforward. Several symptoms, however, may indicate an issue with the flywheel or the clutch:

- Strong vibrations felt in the engine and clutch pedal

- Difficulty shifting gears, accompanied by jolts

- A distinctive noise when engaging the clutch (clattering at idle)

However, these signs can be difficult to interpret and may also resemble symptoms of a faulty clutch.

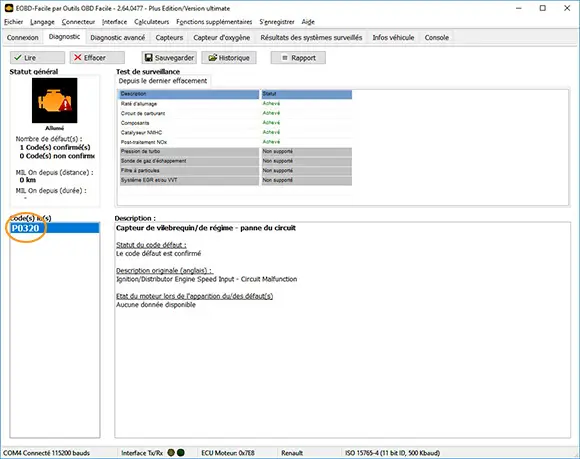

Performing a vehicle diagnostic

Thanks to the crankshaft position sensor, it is possible to carry out a vehicle diagnostic that may return a fault code. Interpreting this will obviously require an analysis of the mechanical parts (a faulty sensor could simply be the issue), but it already provides an indication of the fault, as the symptoms mentioned earlier can be quite hard to observe.

Here, the code P0320 is returned, indicating that the crankshaft sensor detects a fault in the circuit, which could be caused by a defective flywheel.

Note that the crankshaft position sensor can return several fault codes with different meanings, which is why I recommend reading our article on this topic.

Are you looking for a car scanner ?

My flywheel is faulty: what should I do?

If, after several checks, you are certain that your flywheel is faulty, you should replace it as soon as possible. For such operations, it is best to consult a professional, specifically your manufacturer, who may cover part of the repair costs depending on the mileage at the time of failure. However, you cannot expect more than 20% coverage beyond 100,000km...

This is something to consider because the cost of a flywheel ranges between €1,000 and €3,000 depending on the vehicle model. Add to this the cost of a clutch kit, which is highly recommended to replace since some of its components will have deteriorated. Expect to pay between €150 and €500 for this part.

Finally, you must also account for labour costs and associated services, which can make the total bill quite steep...

klavkarr tip: Consider obtaining multiple quotes to compare prices, but don’t forget to leverage your mileage, as this could save you significant money. You may be eligible for 100% coverage for a failure occurring under 60,000km, but not more than 50-70% between 60,000 and 100,000km.