The airflow meter is an essential part of the engine intake, measuring the mass of air entering the engine. It is therefore important to ensure it is in good condition and replace it when it becomes faulty.

Are you looking for a car scanner ?

Function

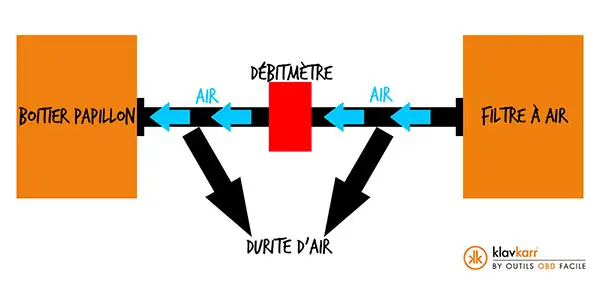

The airflow meter is a mechanical component designed to measure the mass of air (as well as its temperature) entering the engine (air intake) and transmit this information to the engine control unit.

It is therefore located on the intake hose between the air filter and the throttle body to provide precise readings.

The engine control unit

The engine control unit receives the information sent by the airflow meter, enabling it to make precise adjustments to fuel injection and throttle body opening.

Combined with data from the lambda sensor, the control unit can then optimise the air-fuel mixture to improve engine efficiency in real time.

These measurements are also used for the EGR valve, the particulate filter (DPF), and the catalytic converter.

The overall goal is also to minimise the emission of toxic gases to comply with European pollution standards.

Faulty airflow meter?

What are the consequences?

Impurities in the air from the turbo, the EGR valve, or oil vapour recycling (canister) accumulate inside the airflow meter, which over time hinders the sensor and prevents it from functioning properly.

The airflow meter will then send incorrect information to the control unit, causing the injectors (and consequently the engine) to operate abnormally, potentially leading to significant malfunctions!

Note that depending on its condition, it may even stop sending any data if it is excessively clogged! Be sure to monitor its proper functioning!

Symptoms

A faulty or clogged airflow meter can cause quite inconvenient problems. Based on biased data, the control unit will perform improper regulation between air and fuel, potentially causing technical issues that can help identify a problem with the airflow meter:

- Loss of vehicle power (possibly due to the engine entering "limp mode" to prevent significant damage)

- Jerking during acceleration

- Unstable idle speed, frequent stalling

- Starting issues

- Excessive fuel consumption

- Excessive smoke (black smoke)

Additionally, you are likely to emit more harmful particles, risking non-compliance with European anti-pollution standards, which could result in a failed technical inspection!

However, these symptoms may not necessarily indicate a faulty airflow meter but could point to an issue with another mechanical component (catalytic converter, EGR valve, lambda sensor, DPF, spark plugs, etc.).

Testing your airflow meter

How to test it

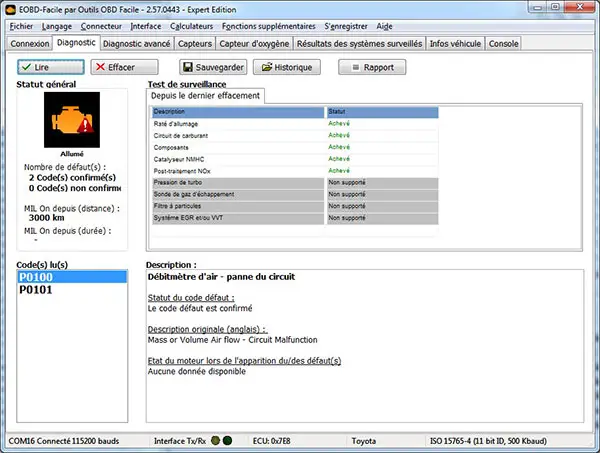

The simplest solution is to perform a car diagnostic with a diagnostic tool, which will provide the OBD fault codes related to a potential airflow meter issue.

The OBD fault codes associated with airflow meter problems are as follows:

- P0100: Airflow meter - Circuit malfunction. In this case, you can clear the fault initially to see if it reappears. Also, check the condition of your air filter and inspect the airflow meter connections.

- P0101: Airflow meter - Performance/limit issue. Clear the fault to see if it reappears. This could be due to low air intake; check the condition of the airflow meter body to see if there is an air leak. Also, inspect the pressure sensor.

- P0102: Airflow meter - Input value too low

- P0103: Airflow meter - Input value too high

- P0104: Airflow meter - Intermittent circuit

For these last three faults, check the voltage as well as the wiring harness (see below).

For more information, I invite you to consult: the list of OBD fault codes. You will find a list of fault codes and their meanings.

It is also possible to directly test the sensor's voltage (older vehicles) and frequency (modern vehicles) using a multimeter to verify that a signal is being emitted.

The displayed voltage corresponds to the air intake by the engine; it should be above 0. When accelerating, this value should increase. If not, your airflow meter is faulty.

To do this, the vehicle must be started and perform accelerations and decelerations. Having a second person present is recommended.

You can also perform a test by disconnecting the connector from your airflow meter to observe if your engine regains power and its issues disappear.

However, be careful not to leave it disconnected for too long, as faults related to the risk of catalytic converter damage, uncontrolled pollution, and overconsumption may arise!

Are you looking for a car scanner ?

Replacing your airflow meter

If your airflow meter is found to be defective, it will need to be replaced. To do this, it is important first to identify the manufacturer and supplier reference to ensure you purchase a compatible one. Sometimes, two references may refer to a single part, so be cautious.

However, the cost of this part is not very high compared to others; it can easily be found for under €100.

It is quite difficult to determine a lifespan for this mechanical part, but generally, it should be replaced after 150,000 km.

Note that it is advisable to replace your air filter at the same time to prevent your airflow meter from wearing out too quickly.